Corrosion-resistant Electronics

Highly flexible sputter coating system for electronic functional layers.

APPLICATION

Copper is frequently used in electronics due to its amazing conductivity and moderate costs, for example, in printed circuit boards, cables and connectors. However, copper forms an oxide layer when exposed to air, which impairs bonding and soldering properties, as well as conductivity. This corrosion problem occurs with connectors, bonding and soldering pads and high-frequency conductors. A thin layer of gold is often used to protect against corrosion. About prevent copper from diffusing through the gold layer, a diffusion barrier is often used between the gold and copper.

REQUIREMENTS FOR THE SYSTEM

The system is designed to coat small plugs or wires, which are fixed to a 150 mm diameter surface on a substrate holder, with corrosion protection. The surface must be cleaned in advance with an ion beam, in order to ensure good adhesion of the coating. The coating should cover the 3D substrates from all sides with the same thickness if possible. As this is a production system, the system must automatically process several of these substrate holders in succession, i.e. it must possess a magazine. It should be possible to add further trial chambers in the future.

- Corrosion resistant

- Required amount of gold as low as possible

- Diffusion barrier against copper

SOLVING THE REQUIREMENTS

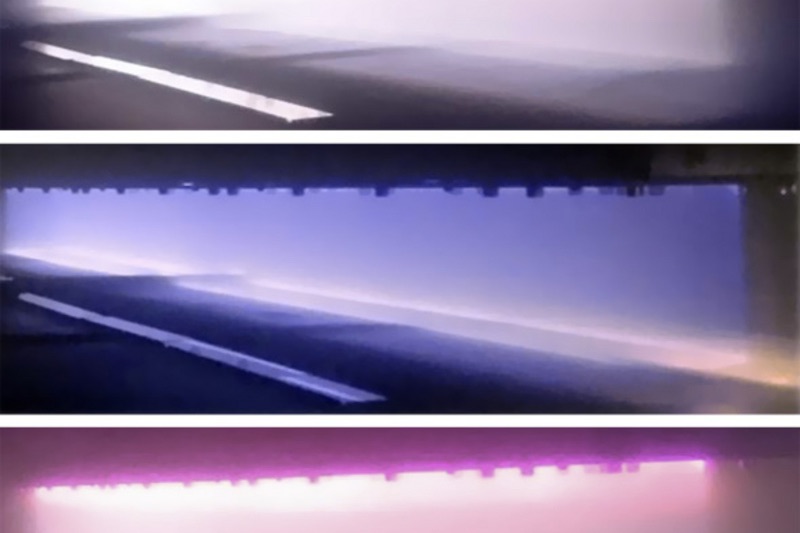

FHR.Star.100-TetraCo is a cluster system with a loading lock, a central transfer chamber with two free ports for future expansion and a process chamber. The loading lock contains a magazine for up to five substrate holders. The transfer chamber robot transports these substrate holders into the process chamber. In the process chamber, the substrate holder lies on a rotating holder for uniform coating. An ion source for pre-treatment and three DC sputter sources for coating with gold or a diffusion barrier are arranged confocally in the process chamber’s lid. Co-sputtering of different materials or equipping with an HF sputter source is possible.

THE SPECIAL FEATURES OF THE FHR.Star.100-TetraCo

- Compact production system with magazine lock for 150 mm wafers or comparable substrates

- Up to 3 different target materials and 1 ion source available for pre-treatment

- Formula-controlled coating with monitoring of all system components and process data logging

Your Contact Person

Do you have any questions?

Would you like to know more about our FHR.Star product range? Our expert, Matthias Rödl, will be happy to help you. Get in touch with us.